This article was updated May 18, 2023. It was originally published Nov. 15, 2002.

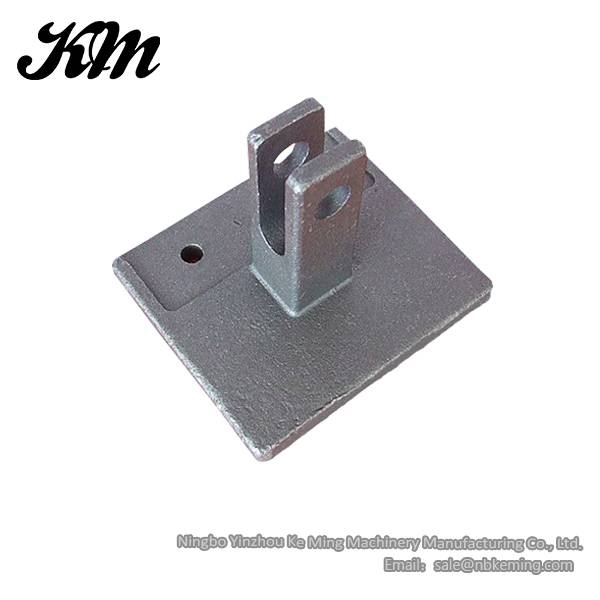

Cast iron, by definition, is any iron alloy with more than 2% carbon and uses that carbon as the main alloying additive. By comparison, steels are less than 2% carbon and usually less than 1% carbon. 2% is the dividing line; below that, the alloy (steel) solidifies as a single-phase material—i.e., austenite—and all the carbon is in the austenite. Cast irons, by definition, solidify as heterogeneous alloys and are made up of than one constituent. Cast irons must also contain silicon, usually from 1 to 3%; so, they are actually iron-carbon-silicon alloys. Custom Forged Part

Although cast iron is often considered a simple metal to produce and specify, its metallurgy is more complex than that of steel and most other metals. This has let metallurgists develop cast irons with a range of properties.

The high carbon and silicon content in cast irons make them well suited for casting. For example, their melting temperatures are appreciably lower than those of steel. Molten iron is also more fluid than molten steel and reacts less with molding materials. And because lower-density graphite does not form when cast irons solidify, they can be cast in complex shapes. Cast irons, however, do not have the ductility to be rolled or forged.

READ MORE: Investment or Sand Casting? Which is Right for Your Application?

The key to cast iron’s range of properties is its carbon content. For example, the precipitation of carbon (as graphite) during provides excellent machinability even when it is boosting at wear-resistance, damps vibrations and helps lubricate wearing surfaces.

Cast irons can also be flame-hardened, induction-hardened and furnace-heated, then quenched with oil. This adds a martensite structure to the alloy. When tempered, martensite provides machinability with maximum strength and good wear resistance.

There are several types of cast iron. Four of the most common are:

Gray iron. This iron alloy contains so much carbon it precipitates out in the form of graphite flakes. These carbon flakes increase the metal’s strength, especially its compressive strength which is three to five times as great as its tensile strength. But its impact strength is below that of most other cast ferrous metals.

Gray iron has no distinct yield point (as defined by classical formulas), so it should not be used when permanent and predictable plastic deformation is preferred over catastrophic failure. Another important characteristic of gray iron, particularly for precision machinery, is its ability to damp vibration. Its damping capability is a function of the amount and type of graphite flakes; as the amount of graphite decreases, so too does the damping capacity.

Gray irons resist wear and even the softer grades perform well under certain borderline lubrication conditions, such as in the upper cylinder walls of internal combustion engines. To increase gray iron’s hardness, which is advantageous if a part will be exposed to abrasive wear, technicians can add alloying elements, or use special foundry techniques or heat treatments.

READ MORE: A Green Way to Make Iron

Gray iron is specified by a two-digit designation. Class 20, for example, specifies a minimum tensile strength of 20,000 psi. It is also specified by cross section and minimum strength of a test bar. The test bar’s cross-section usually matches or is related to a particularly critical section of the finished part. This second specification is necessary because gray iron’s strength is highly sensitive to cross section, with smaller cross sections cooling faster and creating stronger parts.

Typical gray iron applications include automotive engine blocks, gears, flywheels, brake discs and drums, and machine bases. Gray iron serves well in machinery applications because of its fatigue resistance.

Ductile iron. Ductile iron contains trace amounts of magnesium which reacts with sulfur and oxygen in the molten iron and leads to carbon precipitating out as small spheres of graphite. These spheres make ductile iron stiffer, stronger and more shock-resistant than gray iron. Metallurgists make different grades of ductile iron by fine-tuning the iron’s crystalline structure around the graphite, which can be done before casting by formulation or after casting by applying heat treatments.

Adding magnesium to the alloy ends up making ductile iron stronger and more shock-resistant than gray iron. It also has a higher modulus of elasticity, but its damping capacity and thermal conductivity are lower than those of gray iron. By weight, ductile iron parts are more expensive than gray iron parts. But finished parts are stronger with better impact resistance and overall part costs can be about the same.

READ MORE: Comparing Hot and Cold Rolled Steel

A three-part designation lets designers specify ductile iron with defined characteristics. The designation for one typical alloy, 60-40-18, for example, specifies a minimum tensile strength of 60,000 psi, a minimum yield strength of 40,000 psi and 18% elongation in 2 in.

Ductile iron is used in applications such as crankshafts because it is easy to machine, and it has high fatigue strength and modulus of elasticity. It is used for heavy-duty gears due to its high yield strength and wear resistance. And it can be found in door hinges for cars, thanks to its ductility.

White iron. White iron parts are produced by “chilling” selected areas of a part or the entire part while it is still in the mold and just out of the furnace. This cooling is carried out by mounting metal or graphite heat sinks in the mold. When the molten iron then cools, it solidifies so rapidly the carbon cannot precipitate out. As a result, iron carbide (also known as cementite) forms. This process only occurs during solidification.

Both gray and ductile iron parts can be cooled so that the outer layer of some areas of the part or the entire part will harden into brittle white iron. (White iron got its name from its white interior.)

The brittleness, which is white iron’s major disadvantage, can be lowered somewhat by reducing its carbon content or thoroughly stress relieving the part. This turns the carbides into small spheres. However, it also increases costs and decreases hardnesses. But white-iron surfaces and parts are tougher and more easily machinable than gray or ductile iron ones.

Chilling should not be confused with heat-treat hardening, which involves an entirely different metallurgical mechanism.

White irons are used primarily for applications requiring wear and abrasion resistance such as mill liners and shot-blasting nozzles. Other uses include railroad brake shoes, rolling-mill rolls, clay-mixing and brickmaking equipment, and crushers. Generally, white iron costs less than other cast irons.

Compacted graphite iron (CGI), also known as vermicular iron, started out humbly enough as a lab curiosity. Metallurgists knew it was an intermediate alloy between gray and ductile iron that possessed beneficial properties of each, but it was too difficult and expensive to make for it to be used commercially. For example, if the amount of magnesium added to the alloy was off by as little as 0.005%, the results were very low-grade CGI at best.

Advances from academics and working engineers over the years have optimized and simplified the process of making CG so that now foundries know just the right amount of magnesium, titanium and rare earths to add as well as the best processing parameters.

Modern CGI parts have high thermal conductivities, nearly the strength, ductility and fatigue resistance of ductile iron, and damping capacities on par with gray iron. It is also easier to machine than ductile iron.

Before choosing a type of cast iron for an application, engineers should have a good idea about what casting process will be used and what the final product will look like. That’s because the final part’s size and shape control solidification rate and final part strength. Most metals are specified by a standard chemical analysis in which results depend on foundry practice and shape and size of the casting, all of which influence cooling rate. Thus, iron is usually specified by mechanical properties.

READ MORE: Cast Iron and Wrought Iron: What’s the Difference?

When deciding on which type of cast iron, it’s good to know that ASTM and SAE specify them differently. ASTM specifications are based on properties of the specific alloy as determined by tests on an appropriately sized but separately cast test bar. It is poured under conditions the same as the proposed castings will see. SAE specifications, on the other hand, require the cast part’s microstructure be appropriate for the specified grade of metal and that the hardness of each casting at a designated location be tested to ensure they fall within the specified range.

Steel Casting Commercially, the ASTM specification is more commonly used for general engineering applications in which the cast iron must meet the proposed part’s established strength requirements. SAE specifications are usually reserved for large quantities of smaller parts such as those used in cars and trucks and in agricultural and refrigeration equipment. In these cases, a particular grade of iron’s suitability is based on design considerations as well as prototype testing. This is supposed to ensure finished parts will be suitable for the proposed application.